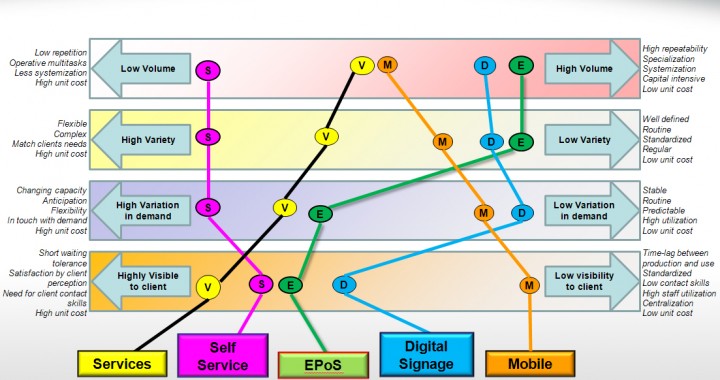

All business processes differ in some way from one another. There are certain common characteristics that all busineses share. If you work strategically within the Operations part of the enterprise you may occassionally find the mix of work difficult to tactically deliver. How do you categorise different types of work and prepare for their oncoming? What are the implications for the company as you try to manage these different types of work? Can you have a meaningful discussion with the Business Development team about how we need to manage this workload? This is where strategy and tactics often collide – BDM sells infinite capacity and the PM has to work with finite resources. Visualising complexity can help…Enter stage left Nigel Slack and the 4V’s model

Volume:

Does the business produce a few specialist items or is it producing lots of the same thing? High volumes of output indicate repeatability due to familiarity of the process. Specialized staffing and machinery may be evident to maximise efficiency of the operation. Economies of scale may be apparent in terms of price point entry to a market. They are doing the same thing again and again so can gain a competitive advantage over a business that has low volume. How does your company fair with the volumes? Do you batch produce; Blue widgets on Monday and Red widgets on Tuesday? Or do you balance your line to produce blue, red, blue red etc.. Each has it merits but the challenge remains to consume stock and human capacity at the rate it is needed, minimising waste and delivering just in time.

Variety:

Focussing on the different types of activities that are being performed. If it is mixed model manufacturer engaged in lots of fast changeovers between processes it will encounter additional operational complexity. If your operations are predominantly filled with a ‘variety’ of work you will need a multi-skilled workforce, simplified work breakdown structures, an efficient parts processing system and a robust order processing system.

How do you fair to your competition? Are they challenged by variety? Remember that a company that manages 100’s of SKUs may not be as focussed and agile as one that handles a dozen SKU’s

Variation:

Processes are always easier to manage when there is predictability of demand. Resources can be more effectively utilised to meet the customer needs. In a process that has unpredictability extra resources will have to be made available to act as a ‘capacity cushion’ against a sudden surge in demand. I operations we talk about flood capacity, buffer stock and a bit of slack. These bely the fact that companies with high variation in demand, forecasting is complicated, stock management can be challenging, people management requires a flexible workforce and there needs to be plenty of margin in your work to cover the trough between the peaks.

Visibility:

How much of the process does the customer actually experience. In a factory that produces skateboards the customer will experience little if any of the process that makes the item, but will enjoy the output – the longboard. Due to a distance between the customer and the process there is an inevitable lag in communications – moments stretch into days and weeks and this can disguise responsiveness of the Operations. However consider the Ops Manager in charge of Nike ID – the custom footwear manufacturer. She or he will have to demonstrate a high degree of capability as indeed will their facility. If the customer is part of the creative process and the recipient of the finished good, this can force the manufacturer into an act of co-creation wherein each and every element of the order process is scrutinised and challenged.

In such an environment standards are extremely high and the ‘customer experience’ becomes part of the Operational activity. This requires a certain type of Manager and a certain type of workforce. Could your operations processes cope with customer engagement?

Visualising:

Plotting the processes that exist within your enterprise will offer you insight into how you would conduct such Business As Usual (BAU). It is not uncommon to have separate teams and procedures in place to deal with processes that have such varied characteristics. Indeed BAU can only occur if one is prepared to accept that the business processes must reflect the needs of the customer.

The ultimate goal of Operations Management is to enable your company to be self sufficient, for your processes to be optimized for maximum efficiency and for your strategic direction to be led by enhanced capability, flexibility and innovation. Such an organization is in control of its processes and its cost centres. A strong Operations analysis of the types of work will offer insight, enabling you to configure your business, taking your profitability into the Beyond.